Let’s talk tips on squaring walk-in box installations, a topic that rears its ugly head every once in a while.

As a manufacturer of a custom product, we are very aware of the fact that our manufacturing process is primarily a human-based process and that on any given day, no matter how many QA or QC processes we have in place, an error can and will slip through the cracks. As with any reputable company, when this happens, we own it and we will take care of the issue.

As with manufacturing, installing a walk-in is a human process and on any given day, you may have a veteran installer that has a bad day, a new installer who isn’t sure of the process or someone who is in a hurry and tries to cut corners. This results in several issues that we are intimately familiar with and below I discuss the tell-tale signs that you can look out for in your projects.

Overhanging or Undershoot Ceiling Panels

Let’s start with the issue of ceilings hanging over the outside wall of the box or not quite making it all the way to the outside. This usually is more pronounced at one end of the box than the other but below are two photos showing the same box at two ends.

We often hear the complaint you made the ceiling panels different sizes. In a case like this, the first thing to do is to throw a tape on the panels. In most cases, they will all measure the same length or to within a 1/16th of an inch.

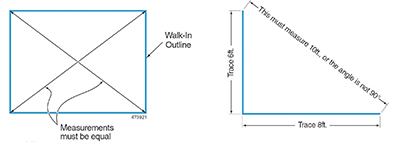

So if all the ceiling panels all measure out the same size, what’s the cause? It’s a pretty simple answer, the box wasn’t squared during install. Squaring a box is easy enough to do, take the measurements, throw down a chalk line and measure from corner to corner and do a little math. Once the box outline is square, the ceiling panels will fit as intended on the top of the box.

Wall to Ceiling Gaps

The next thing we tend to see quite a bit of out in the field is when the walls are stair stepped or there’s a gap between the ceiling panel and the wall at one place or another. Again, we often hear that our panels are not the same length. As discussed above, unless they are way off, meaning over an inch, this is not typically going to be the panels, the likely culprit is that the floor isn’t level. The photos below illustrate what this looks like.

Everyone has different tolerances but a good rule of thumb is that the floor should be level, within 3/16th of an inch per 10 feet of distance. If this is not the case, then either the floor must be floated to level or the wall panels will need to be shimmed in order to level out the panels.

Doors Plumb and Square

One of the biggest issues we see with doors not operating smoothly and correctly once installed has to do with the door section being installed out of plumb or if the door frame gets installed out of square. In both of these instances, the doors will either be difficult to open or they won’t close correctly and the door will have uneven gaps around the frame; meaning, at some locations the door will be closer to the frame while at others it will be further away.

Summary

Boxes installed out of square or on uneven floors account for many of the calls our service department receives about the fit and finish of the box. However, as mentioned at the beginning of this article, building custom equipment is a human process and there will be errors from time to time. When this happens, the panels will typically be way over or way under sized because we got something wrong at the factory. Our statistics show it happens on about one out of every 900 to 1,000 jobs. However, these two issues can be resolved in 98% plus of the cases by insuring the boxes are installed square and on a level surface.